PepsiCo Internship

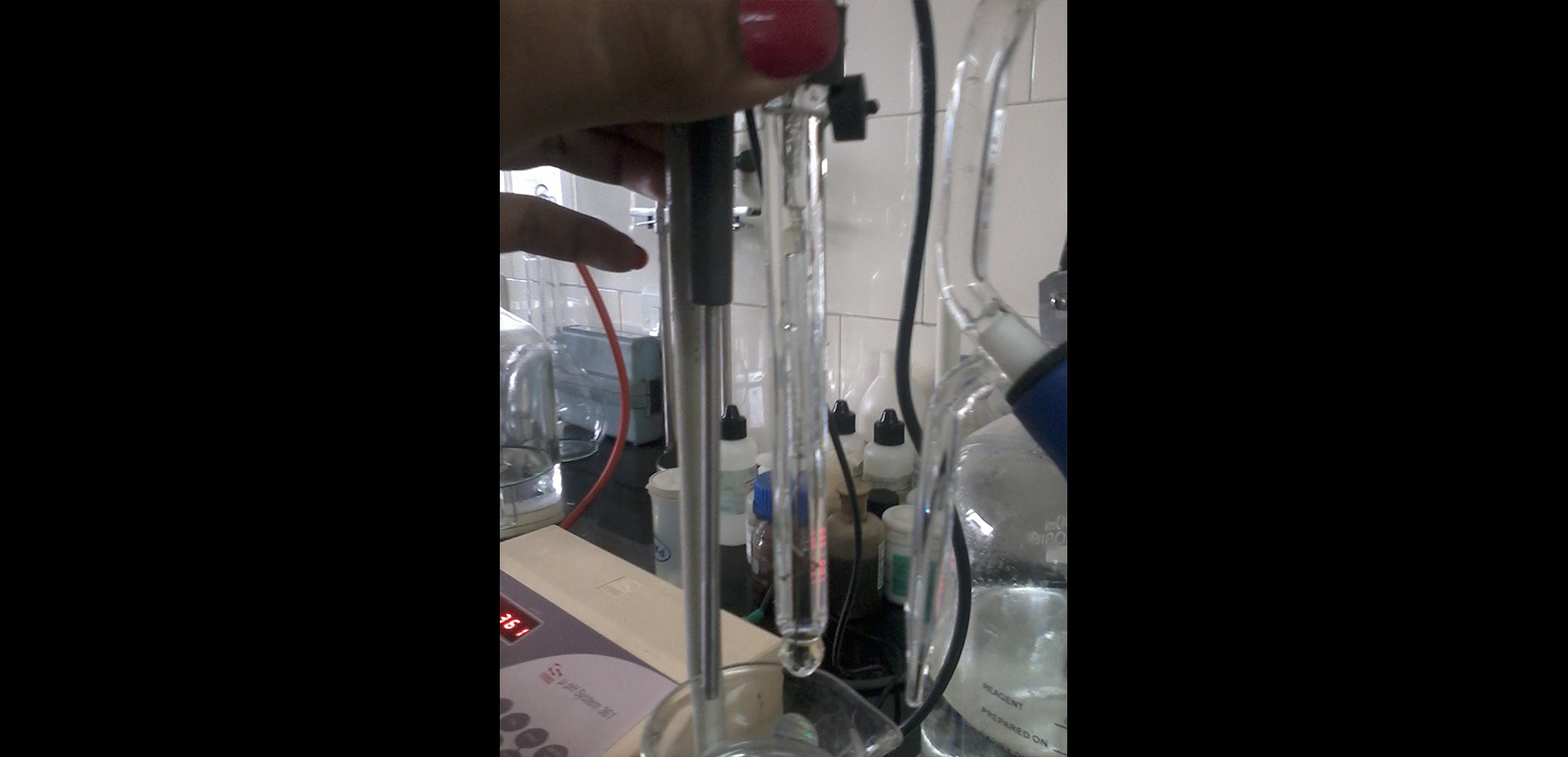

The internship at PepsiCo Ltd. gave me the first exposure in the industrial biotechnology world. I worked in the Microbiology department under the supervision of Ms. Mukta Rani, the head of the non-carbonated drinks department. The training involved the study of the different quality control measures involved in the manufacturing and packaging of the fountain drinks. The training was designed in a way to first study the properties and tests of mineral water, and then move on to the beverages. I studied the stages of purification of ground water and its conversion into drinkable water. This involved the use of activated charcoal purification stage as well. My job role involved checking the hardness, pH, and turbidity of water after every stage. Once a batch of water was purified and filled into the bottles, a sample from each batch was tested for QA (quality assurance) before it was delivered to the market. Tests such as coliform test, conductivity test, chloride test, and microscopic particle count test were conducted. In addition, I studied the manufacturing process of the non-carbonated drinks and carbonated drinks, and their quality control tests. This majorly involved testing the microbial concentration in the drinks, by using the pour plate technique. One of my favourite experiments that I conducted was the Bursting test to measure the strength of the packaging cartons. The repeated requirement to conduct these tests over a period of a month honed my titrimetry and plating skills. This internship not only enhanced my microbiological laboratory skills, but also my ethics to work in a corporate environment.